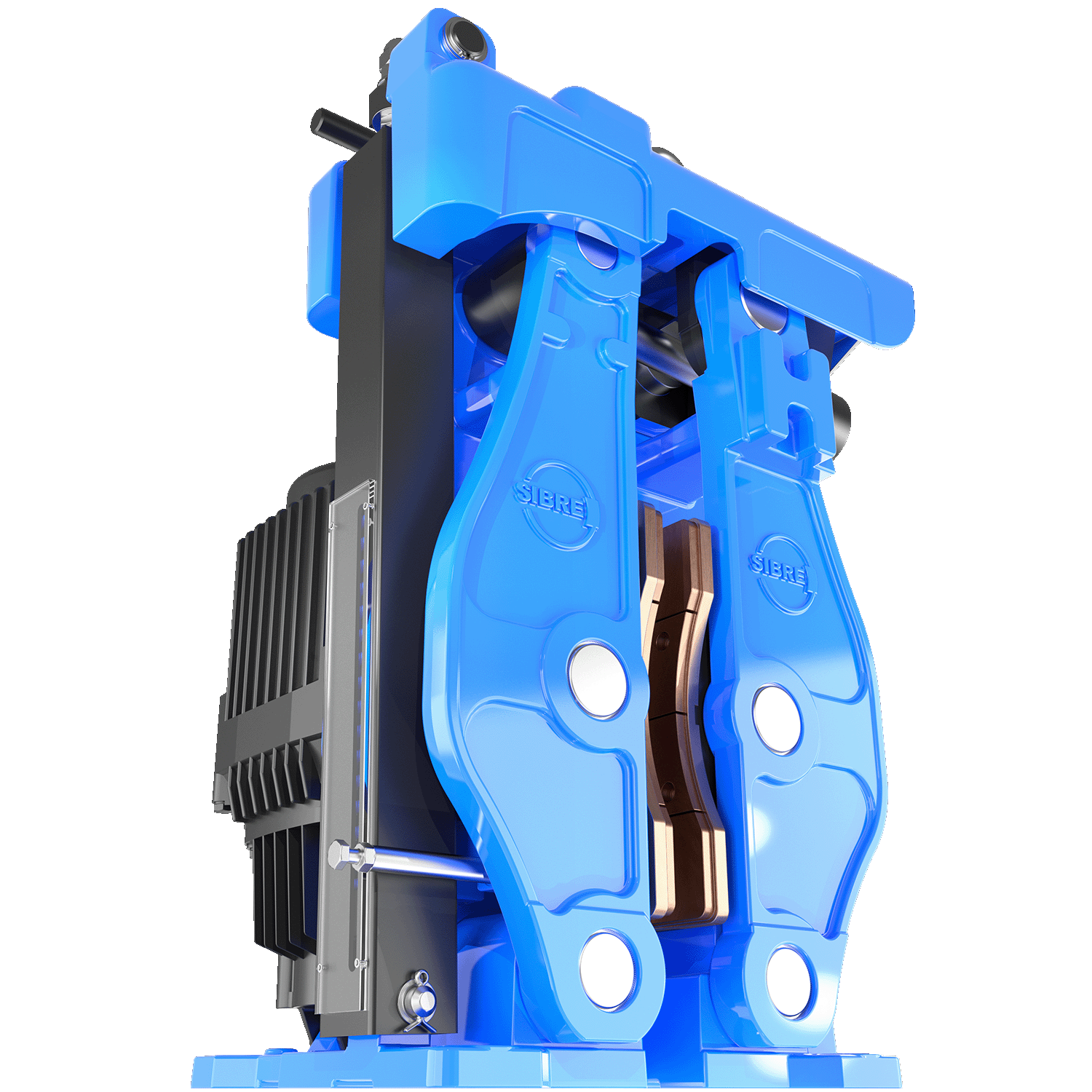

USB 5 V

Braking torque:

6.000 – 29.000 Nm

Peak height:

280 mm

Weight:

285 kg

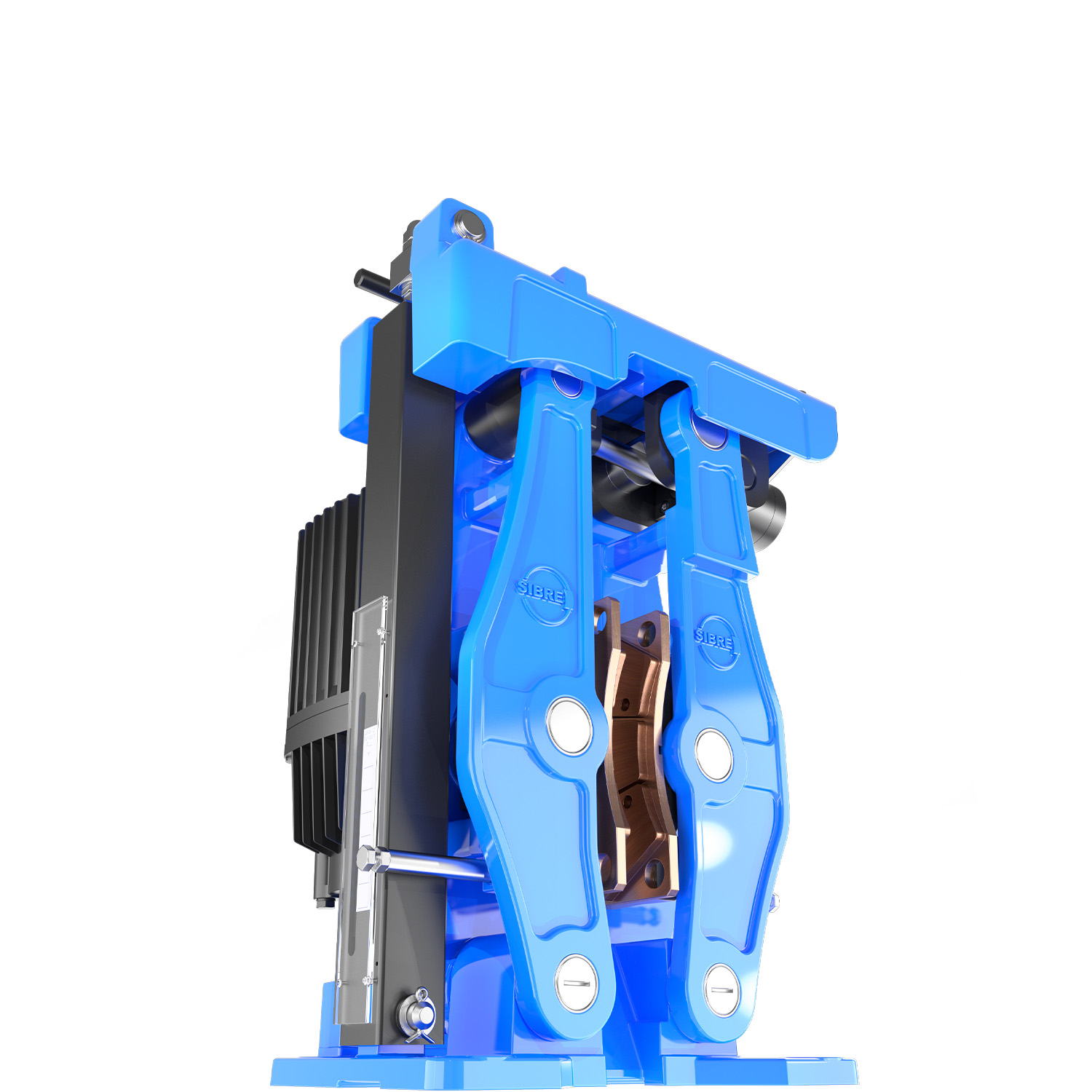

USB 5 III

Braking torque:

3.500 – 26.000 Nm

Peak height:

370 mm

Weight:

250 kg

Datenblatt ansehen

USB 5 II

Braking torque:

1.300 – 9.800 Nm

Peak height:

280 mm

Weight:

175 kg

USB 5 I

Braking torque:

550 – 5.500 Nm

Peak height:

230 mm

Weight:

85 kg

USB 5 05

Braking torque:

110 – 1400 Nm

Peak height:

160 mm

Weight:

46 kg